The ESTEPE More Truck Team now consists of 16 Engineers with various disciplines (Research, Development, Testing, Project, Product, Application, Process and Homologation). Automotive Engineering has become indispensable in the design and development of the current truck modifications at ESTEPE.

At ESTEPE, new products are tested in advance for technical feasibility and then worked out in detail and prepared into a first prototype. To this end, the R&D Team has state-of-the-art tools, in which ESTEPE has invested heavily in recent times.

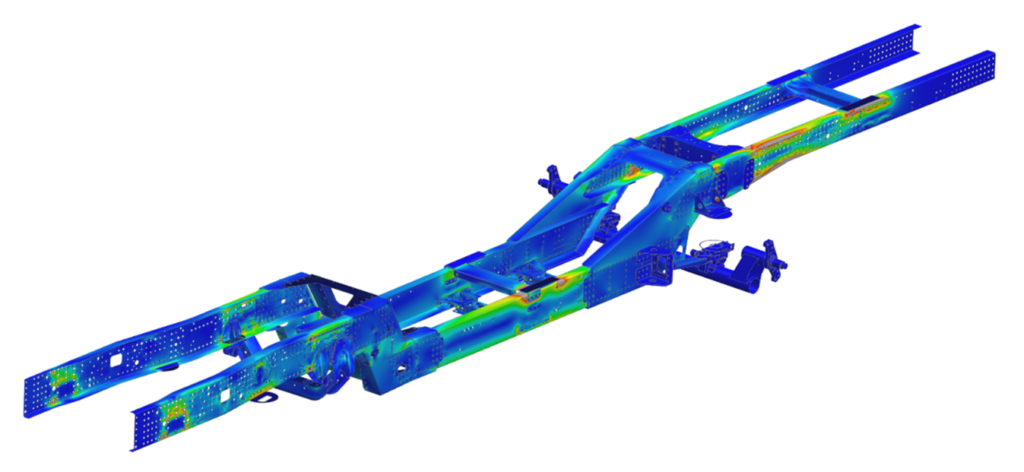

FEM (Finite Element Method) analyses have been performed at ESTEPE for many years. Two years ago, ESTEPE took the next step by purchasing Siemens Simcenter 3D. This is used to calculate, among other things, extensive R29 cabin simulations, R14 seat belt calculations, but also complete chassis drops. Terms such as Back-to-Back validation, static linear and bi-linear simulations are not unfamiliar to ESTEPE.

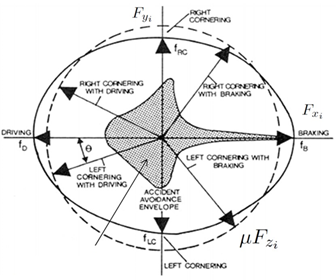

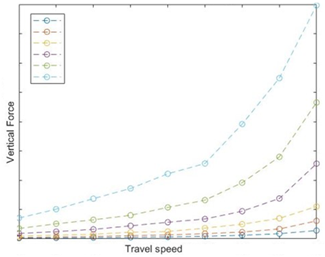

Normal axle loads, brake and steering forces are nice static reasonings that can be used in construction calculations. But what is the real horizontal and vertical dynamics of a truck? How does torsion arise in an axle / chassis and what are the associated dynamic loads? In order to understand all these variables, ESTEPE has performed an extensive literature and field study, in order to bring the calculations to a new level with an improved correlation to reality.

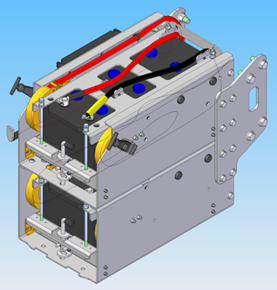

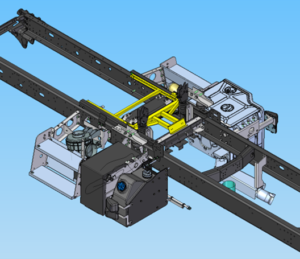

When the truck industry came to a standstill due to Covid in the spring of 2020, ESTEPE seized the opportunity to take a new path with its digital transition. Modular design with overcomplete models makes Configure to Order (CTO) possible, so that not every order has to be engineered/prepared via Engineering and a shorter lead time is possible. Transition to everything in 3D, or the Digital Twin, starts with the release of 3D models from the truck industry and suppliers. After which ESTEPE adds all components in 3D to arrive at that Twin. In addition to better predictability, instructions towards production are also more detailed. No more loose drawings/diagrams in production, no Paperless Workshop is what ESTEPE is going for. All mechanics have their own personal tablet where diagrams, drawings and instructions can be consulted, so that Production always works according to the latest status of released documentation.

In the meantime, 15% of the vehicles converted at ESTEPE already have an electric driveline. In order to be able to convert these vehicles with high-voltage systems, the R&D Team is trained and NEN-9140 certified.

The ESTEPE More Truck Team is fully prepared for the future.